Looking to convert JPG to DST file format online? Great to see you have visited the right place. We provide custom embroidery-related services. In Digi Embroidery, you can order to convert JPG to DST embroidery file or any other embroidery format. Also, you can download free DST files for embroidery machine. Here I will guide you step by step on how to order to convert your JPG files to DST format. Feel free to contact us for any queries about DST or any other embroidery file.

To order your JPG to DST embroidery file conversion, first you need to submit your JPG image to us. There are few options available to send your image for the conversion. The best and easy way to do that is through our contact page above. Send us your JPG image to convert for embroidery file format now. After you send your JPG image, you will receive a quote for the conversion. Once you approve the quotation, we will send you the next process on how to place an order. This is the first part of our custom JPG to DST file conversion.

Also, if you are looking for free DST design files, we also have availabe options for you. We have a seperate sections where you can download free DST files and other formats embroidery designs for free. You will get the link below where you can download DST files for free. Let’s talk about the first process in detail here first.

JPG to DST File Converter

How to order to convert JPG to DST file format from our website?

1.At First,Visit our Contact Page or Order Custom Digitizing page first.

2.Then,Upload your JPG or image files.

3.Write some details about the size and file format that you need etc.

4.After that, Enter your name and valid email address so we can contact you shortly.

5.Once you have done these processes, sit back and relax. Our team will check and reply to you shortly.

6.After checking we will send you a quote as per the files.

Custom Hat Embroidery

The Rising Trend of Personalized Embroidery in Fashion

Exploring the World of Machine Embroidery

CUSTOM BUISNESS LOGO EMBROIDERY

The Rising Global Demand for Custom Embroidery

Elevate Your Designs with Precision Stitching

Custom Logo Embroidery

Transforming Designs into Precision Stitch Art

Digitize File for Embroidery

Tips and Tricks to Get High Quality Embroidery Output

EMBROIDERY NEAR ME

Skills and Knowledge Needed For Starting Embroidery Business

The Rise of Embroidery as a Form of Customization

Are Embroidery Needles Different from Sewing Needles?

Kinds of Stabilizer or Backing Used For Embroidery

7. We offer very affordable pricing for custom digitizing or JPG to DST converter.

8.Then if you approve the pricing, we will send you the next step to place an order.

9.Place an order in one click to convert your JPG to DST format.

10.Just wait we will send the DST file in a quick turnaround.

11. we take 2 to 24 hours for basic orders.

12.We will send you design files in your mail in a faster time frame.

13.It’s done now, you can send the DST files to your embroidery machine and run.

How A JPG To DST Converter Free Software Works?

It’s important to note that converting JPG to DST is a complex process that requires a skilled digitizer with experience in embroidery software. If you’re not familiar with digitizing, you may want to consider outsourcing the task to a professional embroidery service like Digi Embroidery. We have the expertise and equipment to convert your JPG image into a high-quality DST embroidery file that will look great on your finished product.

Here’s how you can do it if you already have a Image to EMB converter free software:

- Choose a good quality JPG image with a resolution of at least 300 dpi.

- Open your embroidery digitizing software that supports DST format. There are many software available in the market, such as Wilcom, Pulse, and Tajima DG/ML.

- Import the JPG file into the software. Some software allows you to drag and drop the file directly onto the workspace, while others require you to import the file manually.

- Adjust the image size, orientation, and color to match your desired output. You can also crop the image or remove any unwanted elements.

- Trace the outlines of the image using the digitizing tools in the software. This process is called “vectorizing.” The software will convert the image into a series of stitches based on your digitizing settings.

- Adjust the stitch density, underlay, and other embroidery parameters to optimize the stitch quality and reduce thread breaks.

- Preview the design to ensure that it meets your expectations. You can simulate the stitching on-screen to see how it will look on the final product.

- Save the design in DST format. Make sure to give the file a descriptive name and choose a location where you can easily find it later.

- Send the DST file to your embroidery machine or a professional embroiderer who can stitch the design onto your desired fabric.

Why Do We Need To Use Image or SVG To DST File Converter?

The basics for the DST file format for beginners is quite easy to understand. This this section I will tell you some history about it. So, you can understand why we need to use svg to dst converter online and how it works on machines. First, I will try to explain what is the computerized embroidery actually. And then will describe the importance to convert JPG to DST. Let’s start with the computerized embroidery part. All the embroidery was done manually by hand since beginning. But in the last century, scientists thought about how we can do it faster and cleaner with a machine. And then they have started working to make the computerized embroidery machine.

Finally, they have succeed to make the computerized embroidery machine. And then day by day they have updated the technology and we reached here today. There are many companies worldwide who are making advanced technology computerized embroidery machines now. But there are some low-class machines are available too. Before buying an embroidery machine, need to know which is the best in the market. So, the DST is a design file foramat for the machines. Any embroidery machine cannot read JPG or any image files. That’s why we have to convert it to a DST or any other machine readable file format. In this way we run our embroidery machine with the DST designs.

JPG to EMB File for 3D Hat Embroidery

Is It Possible To Convert JPG To DST In Photoshop Or Illustrator?

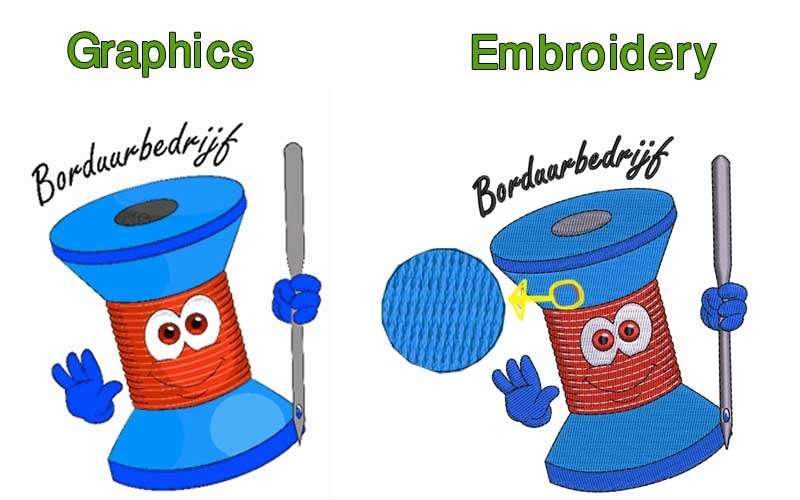

No, we cannot convert JPG image into DST in Photoshop or Illustrator software. Because the Photoshop and Illustrator software is compatible for the flat graphics, images or vectors but the embroidery isn’t something like flat images like JPG or BMP. It is a file of punching that is generated or punched manually in an embroidery software. Also, we need to specify each section of an embroidery design to adjust thread spacing and stitching technique. But a graphincs do not have anyhing like that. To do that, we need a digital design file. Also, we call it a punching file. It’s a machine-readable design file format. The DST is one of those. It’s a machine-readable format that we use on the machine.

That’s why we convert JPG to DST format. It helps the machine to recognize the file, colours, sizes and stitching techniques. Not only convert JPG to pes, but you can also convert any image file like PNG, PDF, AI etc. Even there are tons of different kind of embroidery formats in the market. But the DST of the king of them. Almost 60 percent of embroidery machine can recognize this format. Also, PES, DSB, JEF, VP3, PEC, EXP etc are the most common embroidery design format.

So, before doing any embroidery on computerized embroidery machine, you must need to Convert JPG image to DST or other design format. So, the machine can read the design and stitching. Then the machine will be able to embroider your design on your fabric.

Convert JPG to DST Format Online

Ways To Do All Over Embroidery After JPG To EMB File Conversion

There are some tricks people don’t know much about. We can split big designs for small frame or hoops. For example, your embroidery hoop size is 7 inch but you want to do a 12-inch design. In that case, you can split the design into two parts. So, the embroidery will join together at the joining point. This way you can do the big designs in the small hoops or frames. Now come to the point about the all-over embroidery.

The all-over embroidery is a big and continues design that used to embroider the long fabrics. Also, for the door cover, window cover, table-cover, doormat etc can be done in all over techniques. There are many processes in all-over embroidery. Here I will try to describe some of them for you.

- Center starts point technique

- The Left bottom corners start point

- Right bottom point

- The Left top convert jpg to dst technique

- The Right top point etc to brother pes.

These are the main points where we can keep the design start point for all-over embroidery. Also, some other techniques might be used in the all over as well. So, let’s describe these 5 points to you in this article.

1. First, you have the Center start point technique.

This means the start point of the split part of the design start point will stay at the centre of the design. So, the operator of the machine can adjust it accordingly with each part. Also, sometimes the point in the centre creates a problem for some kind of designs. That’s why you have to know about all over embroidery requirements. Otherwise, you will not be able to match all the parts together to convert PDF to DST.

2. Then you have the option Left bottom corner point.

This is quite good to handle some kinds of all-over embroidery. Actually it depends on the shape of the file. It’s a complex file then you have to check first how you can set the heads together. And if its small logos in all over the bed, then you can keep the point wherever you won’t just have to set accordingly.

3. Right bottom point.

This is the most important part of all type of all-over embroidery. Because when you will do big embroideries like door and window cover, it will help you to join separated heads. Also, sometimes we only use the right bottom start point for big embroidery. It gives the maximum advantage to match the joining areas when convert jpg to dst files.

4. The Left Top

This point is a less using point but you can try. Because always the same start point using is not a good idea. You can balance accordingly with the design. So, you may get better results. The main task is here to join the parts together without problems.

5. The Right Top start point.

This one is also the same as the previous one. These points we use rarely for the special reason if getting problems in the joining. Otherwise, we always use the left bottom and the right bottom for big frames.

These were about the start points of the all-over embroidery. So, it may help you to understand and to do the proper matching.

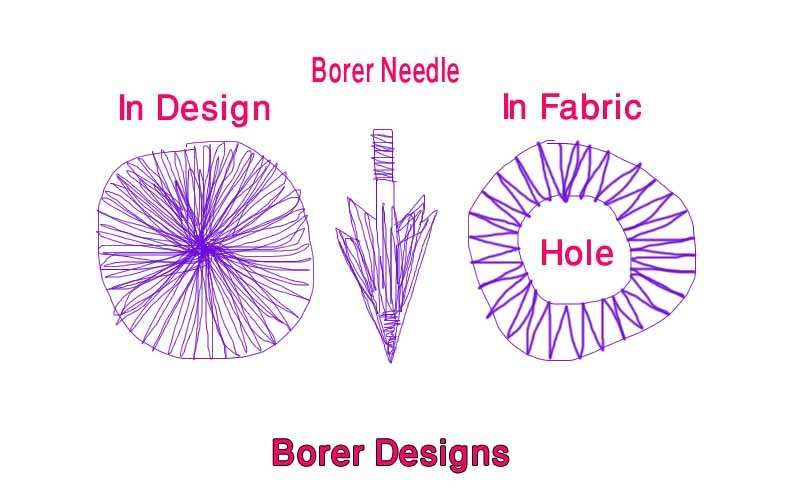

Why To Convert Image To Tajima DST Embroidery File For Borer?

The borer embroidery is one kind of embroidery that makes holes in the fabric to create a borer effect. There are many kinds of borer embroidery available. Not only borer embroidery. Also, there is some other technique embroidery format that creates a hole in the fabric like Laser Bridge, Scify etc. These are the other embroideries that being done with creating holes or bores. Kind of Borer Needles in Embroidery Needle is the material that sews on the fabric using thread that we already know. But the borer needle is different than other needles. Because it has to create some hole in the fabric. So, the needle shape needs to be sharp with angles to cut the fabric. Also, there are some needles available for borer in few options

- Sharp head thick body

- Thick and sharp head

Square shaped uneven sharp head

These are the major kinds of borer needles. Also, sometimes we use broken needles as an alternative to the borer needle. Let me explain to you about these three kinds of borer needles.

1. Sharp head thick body This needle is the most used borer needle in the world I think. Because it actually does not cut the fabric at all. It’s just sharply holed the fabric and breaks the threads. So, when the stitch is done on the borer, the stitch pulls the extra thread and bring well finishing if you can convert jpg to dst correctly.

2.Thick and sharp head Now let me tell about the thick and sharp head needle. This is also an embroidery borer needle for borer machine. This one is a bit different than the previews one. Also, this needle has a very sharp head which completely cot out fabric to create a hole before stitching. Then another needle does the rest to cover the hole with stitch and make a perfect hole and shape.

3.Square shaped uneven sharp head. The square-shaped uneven sharp head needle is another kind of embroidery borer needle and rarely used one. But this needle is good for big holes in the fabric. Also, for small holes as well we can use this. The speciality of this needle is it takes less stitch to hole the fabric. So, using this type of needle take less stitch and less time to complete the design.

Convert Image to DST Border

How Much Cost To Convert JPG to DST Format?

Converting a JPG image to embroidery file format can cost $5 UDS to $20 or more depending on dimension and tecniques. But we provide a very affordable package to convert your files for embroidery. Contact us from above to get a free quote for your embroidery digitizng DST conversion.

Why The Graphics Designs is Less Expensive Compared to JPG to DST?

The main reason for this is complexity. Because when we do graphic logos and designs, we don’t have to separate the colours. Also, we don’t have to adjust the spacing, tie, trims, threads, start, end etc. These things take a lot of time to do and a lot of mental pressure. The graphic is just creating vectors or objects and colour them accordingly. No need any colour separation of steps like embroidery. So, the graphic tale less time than the embroidery design takes. Sometimes it can happen that some design can be critical to doing graphic but less critical to do embroidery.

But this case is very rare and once in hundreds. Now let’s talk about embroidery digitizing file. So, that you can realize why it’s being expensive to digitize a logo for embroidery file.

Why Embroidery Convert to DST is Little Expensive Than Graphics?

Today I will give a brief explanation here about the embroidery and the graphics. So, if you don’t know the reason behind the embroidery then you must need to read this article till the end. Also, if still, you have something to know about this topic after reading the article. Then you can leave a comment below. So, let’s come to the point why embroidery digitizing is expensive compared to graphics. First, let me separate some reasons that are responsible for the expense of the jpg to embroidery file.

1.Manually drawing and shaping embroidery file objects.

2.Separating colours in a sequence and repeat them if necessary.

3.Adjusting the stitch spacing to convert jpg to dst colours, stitch type required etc.

4.Adjusting the tie and trims, start point, stop point etc if necessary.

5.Stitch sequins with stitch and align them accordingly.

6.Position of the panel, the position of Eva and position of applique etc.

7.Placing the applique on the machine, spray the glue behind the applique.

8.Different type of stitching in the applique embroidery digitizing.

9.Taping, cording, beading stitching technique and bartack etc.

10.Chenille stitching creating, effects adjusting, loop size adjusting, chain adjusting etc.

11.Laserbridge cutout preparing, changing options to laser etc.

These are the main factors of the expenses of an embroidery digitizing. If I describe a bit for you then you can clearly understand the reason. And I’m sure you will never ask this thing anymore about to convert jpg to dst, pes. Also, you will forget this question forever that why embroidery is expensive at top rated embroidery digitizers. Let me explain each part of the above objective to you briefly.

Convert Picture to Embroidery File

- Manually drawing and shaping embroidery objects for DST

It’s better for you to know first that the embroidery is a completely manual process done by a digitizer. Because the embroidery machine can’t recognize the flat images. So, we have to digitize them manually object to object to make the file machine-readable. So, the embroidery digitizing takes much time than the graphic and much energy. Also, not only the time, if you are not able to draw the objects properly then you will never get the better quality embroidery. So, the drawing and shaping should be very clean and sharp

- Separating colours in a sequence and repeat them if necessary.

Separating colours is most important in embroidery. This is a complex issue to explain. As because the embroidery objects need to overlaps each other when digitizing. So, that one doesn’t come out from another. So, we have to separate the colours after placing all the objects. Otherwise, the objects will not look good as some are at the top and some are at the bottom. Also, we have to repeat the colours when the same colours object at the bottom. And the same colour objects are at the top.

3. Adjusting the stitch spacing, colours, stitch type required etc.

Adjusting the stitch spacing is depends on the fabric, thread types, and client requirements. Also, the colours are needed to adjust sometimes. The main factor of the stitch spacing depends on the thickness of the fabrics and thickness of the threads. Also, sometimes the design spacing is adjusted accordingly to the client’s requirements when digitize image for embroidery. So, there are a lot things that we need to check manually. Not only the spacing. Also, the stitch type.

Stay connected with by joining our Facebook page of Digi Embroidery to get the updates of convert to DST embroidery file.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on LinkedIn (Opens in new window)

- Click to share on Tumblr (Opens in new window)

- Click to share on Facebook (Opens in new window)

- Click to share on Pinterest (Opens in new window)

- Click to share on WhatsApp (Opens in new window)

- Click to share on Reddit (Opens in new window)