Unlock the power of next-gen embroidery logo digitizing to transform digital designs into high-quality, durable, and precise embroidered logos for your brand.

In the competitive world of branding, companies are increasingly turning to embroidery to bring their logos to life with exceptional quality and durability. Thanks to technological advances, embroidery logo digitizing has evolved into a sophisticated art form, blending the precision of digital tools with the creativity of traditional stitching. The next-gen approach to embroidery digitizing is not just about creating designs—it’s about turning logos into timeless, high-quality embroidered works that enhance a brand’s identity.

What Is Next-Gen Embroidery Logo Digitizing?

Embroidery logo digitizing is the process of converting digital designs—such as logos or artwork—into instructions that embroidery machines can follow to stitch the design onto fabric. The “next-gen” aspect refers to advancements in digitizing technology and techniques, making the process more precise, faster, and capable of handling more complex designs than ever before.

Modern embroidery digitizing allows businesses to showcase their logos with greater vibrancy and clarity, thanks to advancements in software and tools. From fine textures to rich color palettes, next-gen digitizing ensures that every detail is accurately replicated.

The Role of Advanced Software and Tools

Gone are the days when embroidery relied on hand-stitching every detail. With next-gen embroidery digitizing, sophisticated software tools like Wilcom, Pulse, and Hatch work alongside cutting-edge embroidery machines. These tools enable high-precision, high-quality stitching, making it easier to perfect stitch density, direction, and type based on fabric texture and design needs.

Software capabilities such as auto-digitizing, stitch simulation, and real-time editing allow embroidery digitizers to refine designs with the utmost accuracy, ensuring logos are flawlessly transferred to a variety of materials, from soft fabrics to tough denims.

Why Next-Gen Embroidery Is a Game-Changer for Branding

1. High-Quality Finishing

The transition from digital design to physical embroidery is smoother than ever in next-gen digitizing. High-quality finishes are achieved with meticulous attention to detail, ensuring every curve, edge, and line of the logo is represented precisely, resulting in a polished, professional appearance that aligns with the brand’s image.

2. Versatility Across Materials

One of the standout benefits of next-gen embroidery logo digitizing is the versatility it offers across various fabrics. Whether it’s a sleek cotton t-shirt or durable workwear, the embroidery process adapts to different material types. Digitizers can choose appropriate stitch types and thread colors to ensure optimal results.

3. Speed and Efficiency

With modern embroidery machines, brands can create large quantities of embroidered items in less time without compromising on quality. Next-gen digitizing accelerates production, allowing businesses to meet tight deadlines or scale up for bulk orders with ease.

4. Affordable Customization

While traditional embroidery can be costly due to its labor-intensive nature, next-gen digitizing has reduced customization costs, making embroidered products more affordable. This allows businesses of all sizes to invest in high-quality embroidered merchandise or uniforms without breaking the budget.

Key Benefits of Next-Gen Embroidery Logo Digitizing

- Fine Detail and Precision: Every tiny detail, from small text to intricate shapes, is accurately replicated.

- Durability: Embroidered logos last longer, standing up to multiple washes and wear, unlike print-based designs.

- Color Accuracy: Advanced digitizing ensures your brand colors are true to form, offering consistent representation.

- Consistency: Achieve uniform results across multiple items, whether it’s t-shirts, caps, or corporate uniforms.

Trends in Next-Gen Embroidery Digitizing

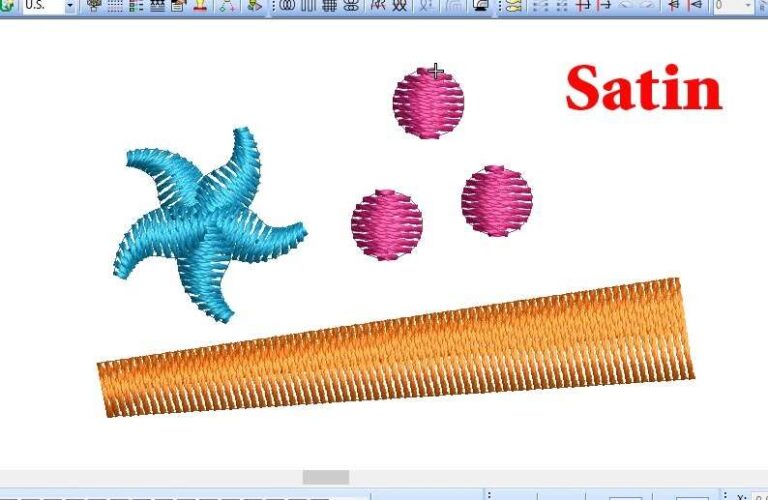

1. 3D Puff Embroidery

One of the most popular trends in next-gen embroidery is 3D puff embroidery. By inserting foam beneath the design, this technique creates a raised, three-dimensional effect that makes logos stand out, especially on caps, jackets, and sportswear.

2. Hybrid Techniques

Hybrid techniques combine digital printing and embroidery, allowing for more complex and detailed designs. This fusion of technologies enables brands to produce unique and eye-catching products with both texture and color.

3. Sustainable Embroidery

As sustainability becomes a growing priority, next-gen embroidery digitizing also incorporates eco-friendly practices. The use of recycled threads, energy-efficient machines, and other sustainable processes is becoming a key feature in embroidery digitizing, ensuring that businesses can align with environmental goals.

The Future of Logo Embroidery

The future of embroidery logo digitizing is exciting, with technological advancements pushing the boundaries even further. Artificial intelligence and machine learning may soon be used to automate the perfect stitch for any design, enhancing precision and speed. As these technologies evolve, next-gen embroidery will continue to improve in accuracy, efficiency, and sustainability.

Conclusion

Next-gen embroidery logo digitizing is revolutionizing how businesses transform digital designs into high-quality, lasting embroidered logos. With enhanced software, powerful tools, and innovative techniques, companies can now create stunning logos that stand the test of time. Whether it’s for customized apparel, promotional items, or branded merchandise, next-gen embroidery ensures your brand’s identity is brought to life in a way that’s memorable, professional, and durable. Embrace this cutting-edge technology to enhance your branding efforts and leave a lasting impression on your customers.